The Power Of Precision: Exploring The Significance Of Moulding Design CAD Blocks

The Power of Precision: Exploring the Significance of Moulding Design CAD Blocks

Related Articles: The Power of Precision: Exploring the Significance of Moulding Design CAD Blocks

Introduction

With great pleasure, we will explore the intriguing topic related to The Power of Precision: Exploring the Significance of Moulding Design CAD Blocks. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Power of Precision: Exploring the Significance of Moulding Design CAD Blocks

In the realm of manufacturing, precision is paramount. Every detail, every curve, every dimension plays a crucial role in the final product’s quality and functionality. This is particularly true in the world of moulding, where the success of the entire process hinges on the intricate design of the mould itself. Here, Computer-Aided Design (CAD) emerges as a powerful ally, and within its vast toolkit, moulding design CAD blocks stand out as indispensable elements.

Understanding the Essence of Moulding Design CAD Blocks

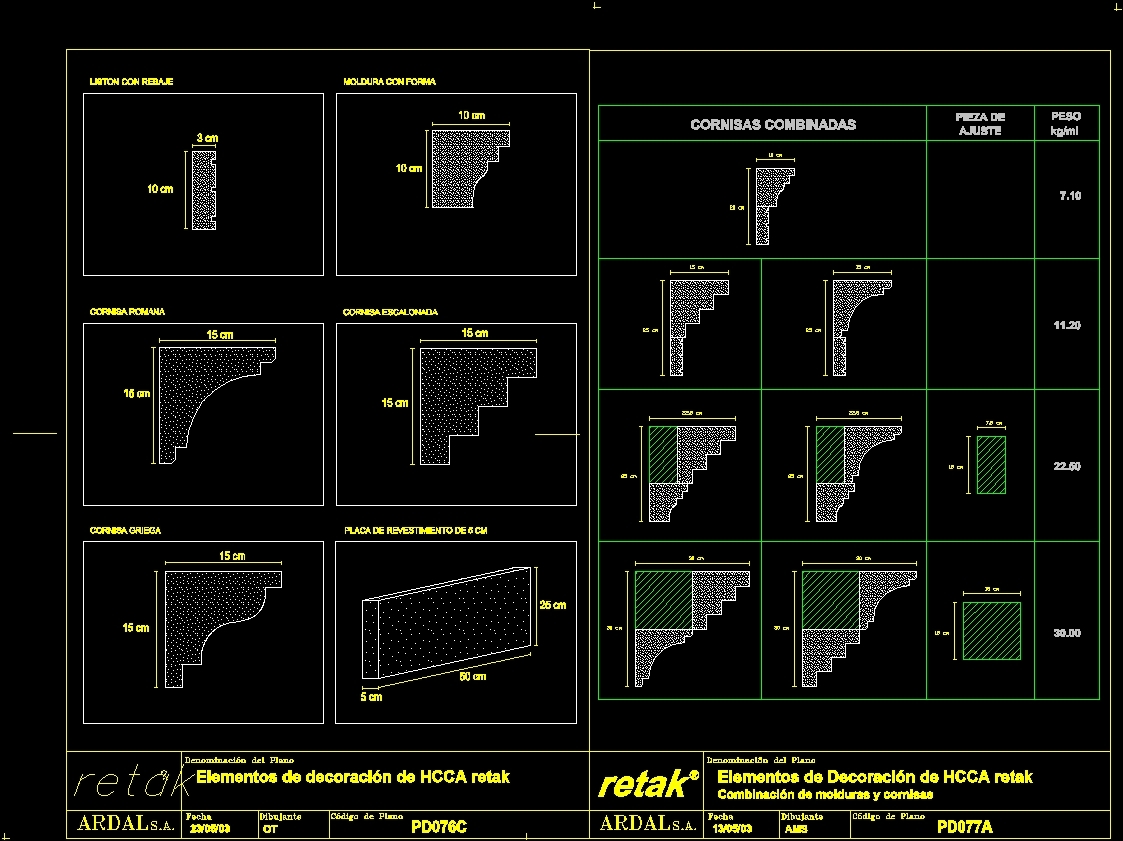

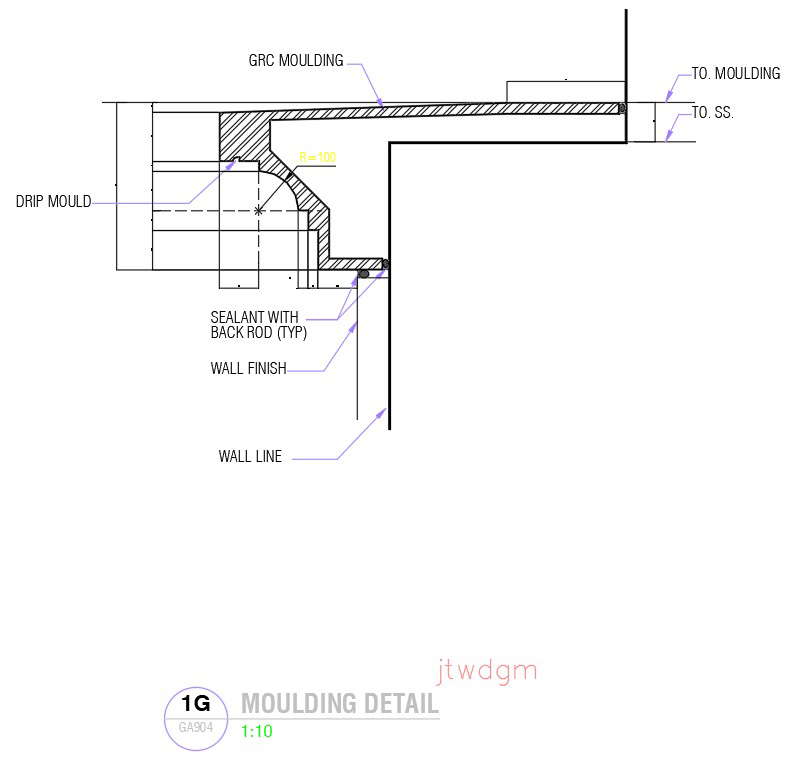

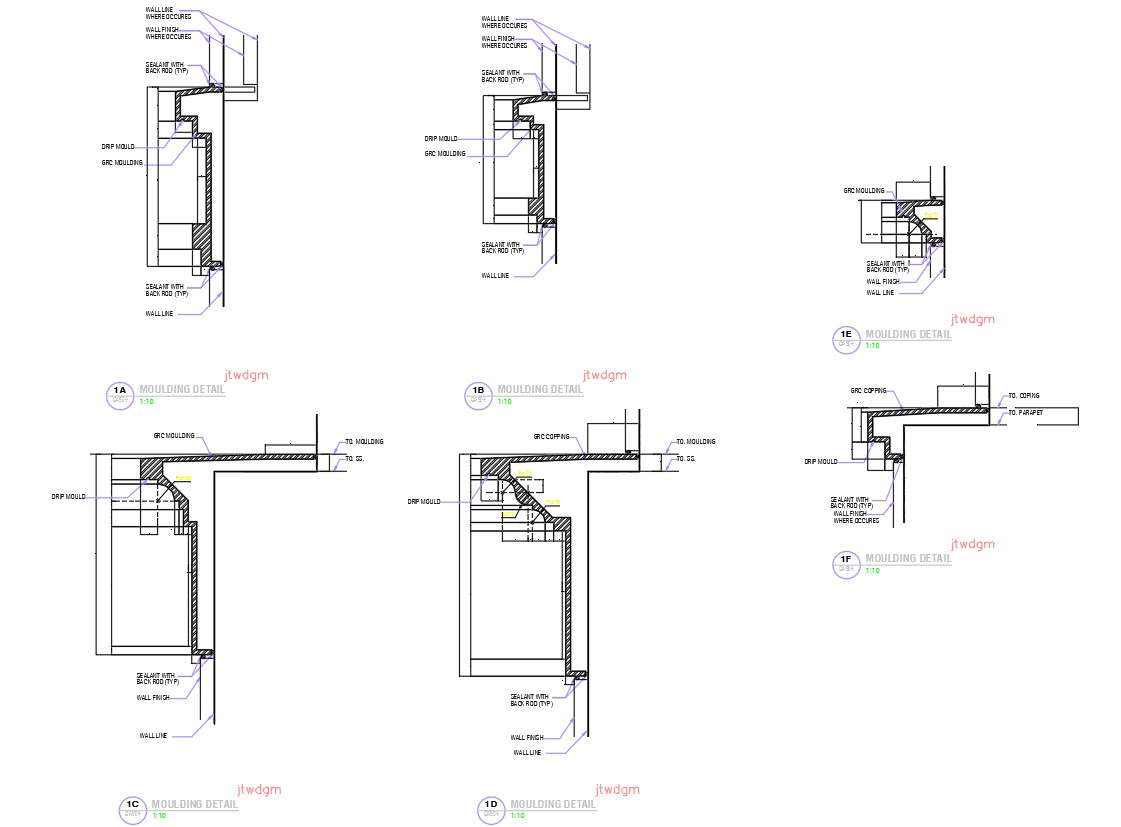

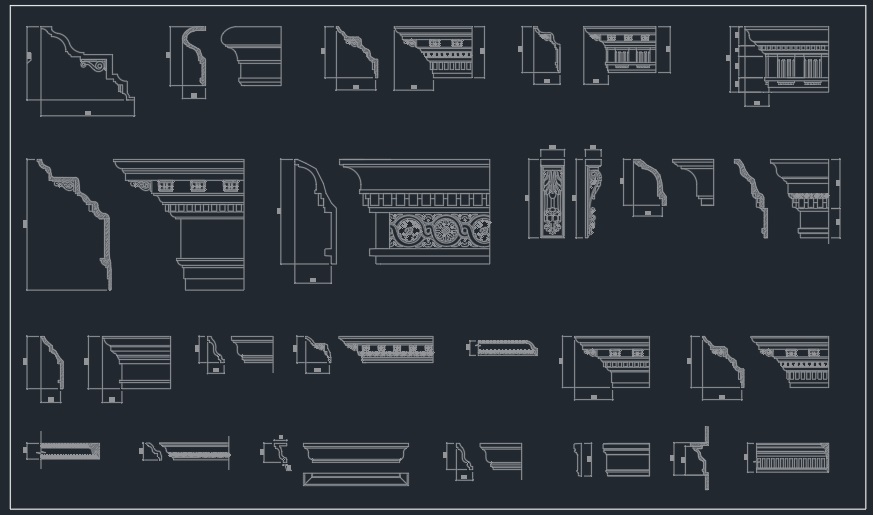

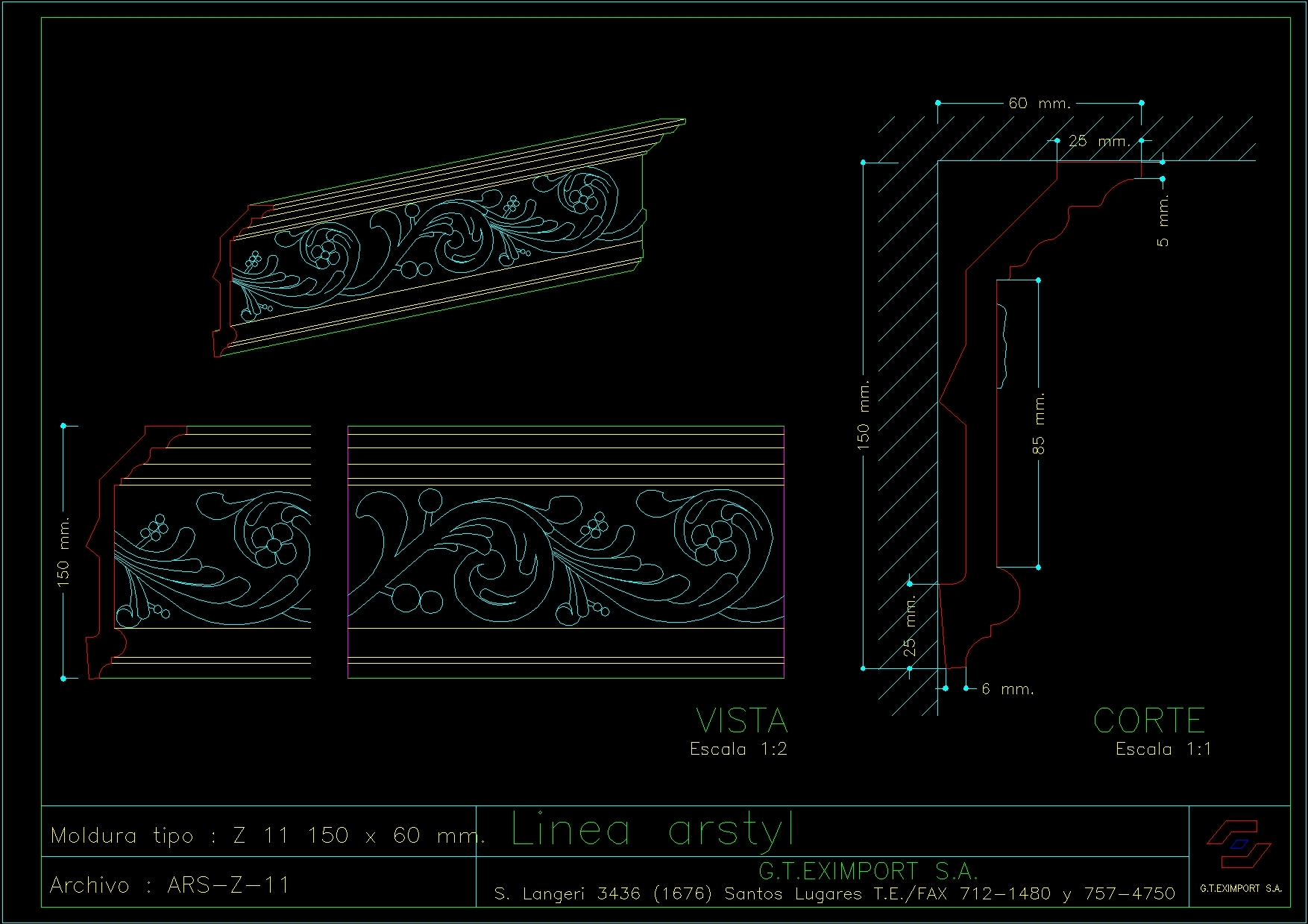

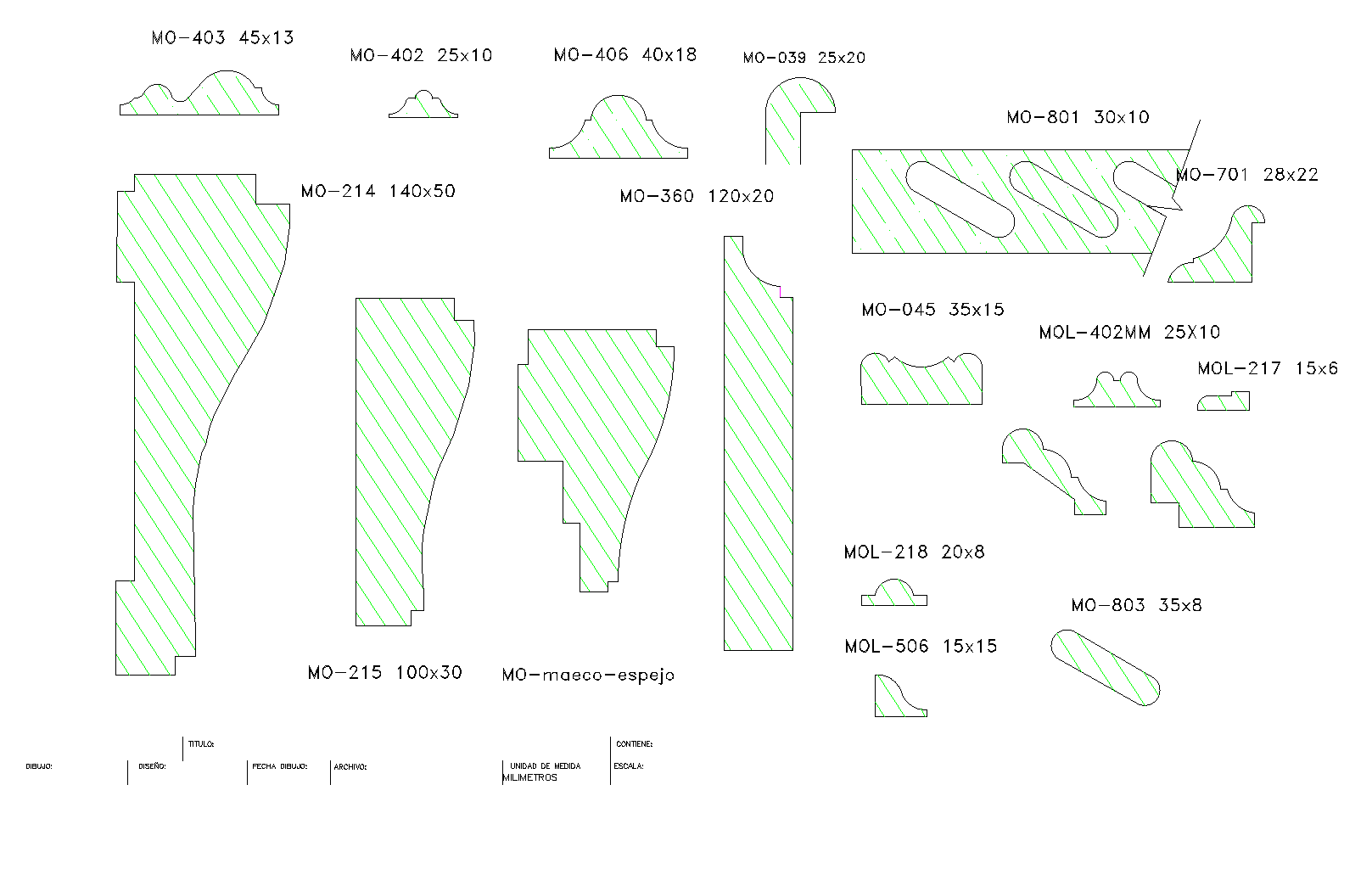

Moulding design CAD blocks are pre-designed, digital components that represent standard features, elements, and geometries commonly used in mould construction. They encompass a wide range of components, including:

- Core and Cavity Elements: These blocks define the shape and internal contours of the final moulded product, ensuring accurate reproduction of intricate details.

- Gate and Runner Systems: These blocks dictate the flow of molten material into the mould cavity, optimizing the filling process and minimizing defects.

- Ejector Mechanisms: These blocks represent the pins and systems that facilitate the removal of the finished product from the mould, ensuring efficient and damage-free ejection.

- Cooling Channels: These blocks define the pathways for cooling water, crucial for regulating the temperature of the mould and ensuring proper solidification of the material.

- Support Structures: These blocks represent the framework that provides structural integrity and stability to the mould, ensuring its durability and longevity.

The Advantages of Utilizing Moulding Design CAD Blocks

The integration of moulding design CAD blocks into the design process offers a plethora of benefits, streamlining the workflow and enhancing the overall quality of the mould:

- Accelerated Design Process: CAD blocks provide pre-built components, eliminating the need for repetitive drawing and modelling. This significantly speeds up the design process, reducing time and costs.

- Enhanced Accuracy and Precision: CAD blocks are based on precise dimensions and specifications, ensuring consistent and accurate representation of the mould’s components. This minimizes errors and ensures a more reliable manufacturing process.

- Improved Collaboration and Communication: CAD blocks facilitate seamless communication between designers, engineers, and manufacturers. Shared libraries of blocks ensure everyone is working with the same design language and specifications.

- Enhanced Standardization and Consistency: Utilizing pre-defined CAD blocks promotes standardization across different projects, ensuring consistent quality and simplifying the manufacturing process.

- Cost Optimization: The streamlined workflow and reduced errors associated with CAD blocks contribute to significant cost savings throughout the moulding process.

Beyond the Basics: Exploring the Different Types of Moulding Design CAD Blocks

Moulding design CAD blocks are not a monolithic entity. They come in various forms, tailored to specific needs and applications:

- 2D CAD Blocks: These blocks are primarily used in 2D drafting software, offering a simplified representation of mould components. They are ideal for initial concept design and basic visualization.

- 3D CAD Blocks: These blocks are designed for 3D modelling software, providing a more detailed and accurate representation of the mould. They allow for comprehensive analysis and simulation of the manufacturing process.

- Parametric CAD Blocks: These blocks offer dynamic control over dimensions and parameters, allowing for easy modification and adaptation to different design requirements.

- Intelligent CAD Blocks: These blocks are equipped with built-in intelligence, allowing for automatic updates and adjustments based on changes in other design elements.

Leveraging Moulding Design CAD Blocks: A Step-by-Step Guide

The successful implementation of moulding design CAD blocks requires a structured approach:

- Identify the Project Requirements: Define the specific components and functionalities required for the mould, considering the material, product design, and manufacturing process.

- Select the Appropriate CAD Software: Choose a CAD software that supports the required features and offers a library of relevant moulding design blocks.

- Explore the Available Block Libraries: Familiarize yourself with the available libraries of CAD blocks, identifying those that align with the project’s specific needs.

- Import and Utilize the Blocks: Import the selected blocks into the CAD software and integrate them into the design, ensuring proper placement and alignment.

- Modify and Customize the Blocks: Adjust the dimensions, parameters, and other attributes of the blocks to meet the specific requirements of the project.

- Perform Design Validation: Conduct thorough design validation and analysis to ensure the accuracy, functionality, and manufacturability of the mould.

FAQs: Demystifying the World of Moulding Design CAD Blocks

1. What are the key considerations when choosing a moulding design CAD block library?

The selection of a CAD block library should be driven by factors like:

- Software Compatibility: Ensure the library is compatible with the chosen CAD software.

- Content Relevance: Verify that the library contains blocks relevant to the specific type of mould being designed.

- Quality and Accuracy: Choose a library with high-quality blocks that adhere to industry standards and ensure accuracy.

- Updates and Support: Opt for a library that offers regular updates and reliable technical support.

2. How can I ensure the accuracy of the imported CAD blocks?

It’s crucial to:

- Verify the Source: Obtain blocks from reputable sources to ensure their accuracy and reliability.

- Check Dimensions and Specifications: Carefully verify the dimensions and specifications of the blocks against the project requirements.

- Conduct Design Reviews: Engage in thorough design reviews to identify and rectify any potential errors or inconsistencies.

3. What are some best practices for utilizing moulding design CAD blocks?

- Adopt a Standardized Approach: Establish clear guidelines and conventions for using CAD blocks to maintain consistency across projects.

- Maintain a Centralized Library: Create a centralized repository for storing and managing CAD blocks, ensuring accessibility and ease of use.

- Regularly Update the Library: Keep the library up-to-date with the latest industry standards and advancements in technology.

- Document Block Usage: Maintain clear documentation of the blocks used in each project, including their source, modifications, and specific applications.

4. How can I learn more about moulding design CAD blocks?

- Online Resources: Explore websites, forums, and online tutorials dedicated to CAD design and moulding.

- Industry Publications: Read industry publications and journals that cover CAD software, moulding design, and related technologies.

- Training Courses: Enroll in training courses offered by CAD software vendors or professional organizations specializing in moulding design.

- Networking with Experts: Connect with industry professionals, designers, and engineers who have expertise in moulding design and CAD software.

Tips for Effective Utilization of Moulding Design CAD Blocks

- Prioritize Quality over Quantity: Focus on selecting high-quality, accurate blocks rather than simply accumulating a large library.

- Embrace Customization: Don’t hesitate to modify and customize blocks to meet specific project requirements, ensuring a perfect fit.

- Utilize Parametric Blocks: Explore parametric blocks to gain dynamic control over dimensions and parameters, facilitating design flexibility.

- Leverage Block Libraries for Collaboration: Share block libraries with team members and collaborators, fostering efficient communication and design consistency.

Conclusion: Moulding Design CAD Blocks – A Cornerstone of Modern Manufacturing

Moulding design CAD blocks have revolutionized the way moulds are designed and manufactured. They empower engineers and designers with a powerful set of tools, enabling them to create intricate, accurate, and efficient moulds. By embracing the advantages of these blocks, manufacturers can streamline their processes, reduce costs, and elevate the quality of their products, ultimately driving success in the competitive landscape of modern manufacturing.

Closure

Thus, we hope this article has provided valuable insights into The Power of Precision: Exploring the Significance of Moulding Design CAD Blocks. We appreciate your attention to our article. See you in our next article!

You may also like

Recent Posts

- The Art Of Persuasion: A Comprehensive Guide To Makeup Product Label Design

- A Comprehensive Look At Mary Kay Cosmetics: Reviews, Insights, And Considerations

- Affordable Skin Care: A Guide To Effective Products Under INR 100

- Navigating The World Of Mary Kay Discounted Products: A Comprehensive Guide

- The Power Of High-Resolution Images: A Guide To Acquiring The Best Visuals For Your Projects

- The Power Of Reviews: Navigating The World Of Makeup Products

- Swiss Beauty Makeup: A Comprehensive Guide To Quality And Affordability

- Embracing Natural Beauty: Makeup Tips And Techniques For Women Over 50

Leave a Reply